Services

Advanced Quality

Planning

Risk...Risk...Risk

EStream's fresh-eyes approach helps

to determine if current processing and systems are robust and suitable, or can benefit

from integrating lessons learned before new program launch. Starting with known

process performance and improvements made as a results of previous risk

reduction provides a good new process start point.

So what further risk still remains, that can impact upcoming process or product

changes? That's what Failure Mode Effects Analysis is for.

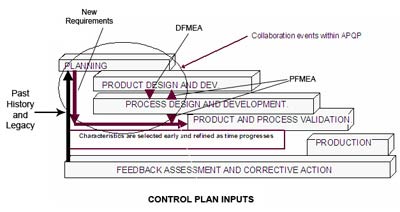

FMEA is the beginning of understanding the workings of your process that affect exposure to product performance and thereby quality/warranty, and delivery predictability. And then changing or adding controls to make it better. The activity is called Advanced Product Quality Planning, or APQP. It does not only get done before a program starts, but should be done at a regular frequency to look for improvement opportunities.

It's a team activity-your team, with our mentoring that investigates and finds solutions. Home-grown solutions, often costing very little, that make your processes more robust to variables both in, and often out of your control. And because they are YOUR solutions, you have an accountable process owner for their benefits, and knowledge to continue to further reduce performance risk.

Launch Assistance

• Early pilot builds

• Assembly and mating parts interaction

• Handling and storage of product

• Ramp-up to full volume

• Ongoing scheduled or contingency liaison if beneficial

Your Customer will understand that you are represented on-site, so that communications can be immediate and effective

Supplier Performance

EStream Supplier Assistance, frees up or supports your resources at

those times when they are better utilized performing higher

priority value added activities.

At the request of you or Supplier management EStream helps your Supplier to determine if assistance is necessary to prevent launch problems or implement permanent Quality performance improvement. We report out to you and/or your Supplier leadership and recommend:

- Weaknesses to be resolved

- What assistance is recommended

- Supplier Training needs to implement

- Oversight and validation of improvement activities

Development of ongoing supplier development, using your performance metric, or one developed for you would be used to measure performance improvement

Skills Improvement

EStream can develop and deliver team skills training customized to your needs, or can provide additional content upon request

- Advanced

Quality Planning, including risk evaluation (FMEA/Control Plans) based on recognized principles of Automotive Core Tools

- Poka-Yoke Error proofing

- Common sense Statistical Process approaches

Lean / Kaizen / 5S

EStream

can help you

understand the opportunities for improvement in your processing that

can be realized using these tools. Improved output, managed

inventories, and processing supervision are outcomes of successful

implementation.

- Match output with demand

- Standardized work

- Improve First-Time Yield

- Reduce Inventory Value

- Free up

resources

EmpowerStream Services provides assistance in the Ontario-South region

Phone: 289-675-5157 rick.beck@empowerstream.ca